Other Machinery

Singapore’s advanced manufacturing sector is witnessing rapid growth, with demand for high-quality precision engineering solutions rising across industries such as aerospace, electronics, semiconductors, and medical devices. As a leader in precision sheet metal fabrication and laser machinery, Sg Laser has solidified its position as a market leader by delivering superior craftsmanship, cutting-edge technology, and unparalleled customer service.

With a commitment to high-quality manufacturing, advanced automation, and stringent quality control, our machines deliver exceptional accuracy and productivity, meeting the demands of modern industries. Trusted by electrical manufacturers and industrial professionals, SG Laser is your go-to partner for cutting-edge solutions that drive efficiency and excellence.

.png)

High Precision Cutting

Multiple Operations in One Machine

Automatic Material Feeding System

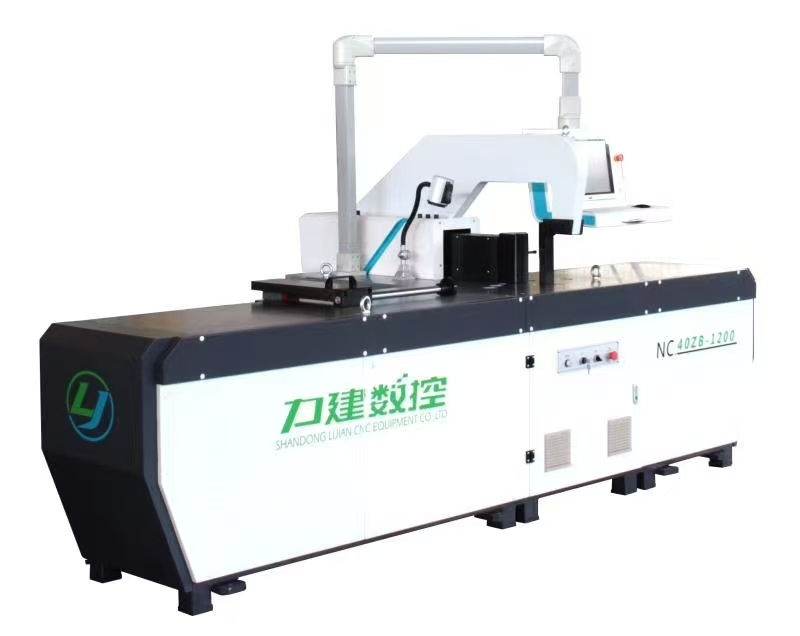

PRECISION BUS BAR MACHINE

SG Laser's precision bus bar machine is a specialized piece of equipment designed to handle bus bars, which are electrical conductors used for power distribution in electrical systems, such as switchgear, transformers, and circuit breakers. These machines are essential for producing bus bars with exact dimensions and high-quality finishes. Below are the key features of a precision bus bar machine that make it highly efficient and reliable in manufacturing high-quality bus bars.

CABLE STRIPPING MACHINE

SG Laser's precision cable stripping machine is designed to efficiently remove the insulation from electrical cables without damaging the inner conductors. It is used extensively in industries such as electrical manufacturing, telecommunications, automotive, and aerospace. These machines offer high precision, speed, and reliability for stripping various types of cables, including copper, aluminum, and fiber-optic cables. Below are the key features of a precision cable stripping machine:

High-Precision Stripping

CNC Control for Precision

Automatic Feeding & Cutting System

Multi-Function Capability

Adjustable Punching Stations

Adjustable Stripping Length

The precision bus bar machine is equipped with high-precision cutting tools that allow for exact length cuts of bus bars. With the ability to process different types of metals such as copper, aluminum, or steel, these machines ensure that bus bars are cut to precise measurements without any deviations. This precision is essential for meeting the stringent requirements of electrical systems, where accurate dimensions and lengths are crucial for efficient power distribution.

A precision bus bar machine integrates multiple operations into a single system. These machines can cut, punch, bend, and even mark the bus bars. By combining multiple functions into one machine, manufacturers can reduce setup times, streamline production processes, and minimize operational costs. This multi-functionality is particularly beneficial for high-volume production, ensuring consistent and efficient output.

Many precision bus bar machines come with automatic material feeding systems that ensure consistent and accurate feeding of bus bars into the machine. The automatic system helps to align and position the material properly, reducing human error and enhancing precision during operations. This feature ensures that bus bars are consistently fed into the machine for each cutting or punching operation, improving the overall productivity and quality of the process.

Adjustable punching stations are a key feature in precision bus bar machines. These punching stations can be adjusted to accommodate various hole sizes and patterns needed for electrical connections. The flexibility of the punching stations ensures that bus bars can be processed for multiple electrical applications, such as mounting hardware, screws, or terminal connections. This versatility allows manufacturers to produce bus bars for a wide range of electrical systems, from industrial to commercial and residential applications.

Customizable Cutting & Bending Parameters

The ability to customize cutting and bending parameters is a valuable feature of the precision bus bar machine. With adjustable settings for cutting length, bending angle, punching hole size, and material feed rate, operators can tailor the machine’s operation to suit the specific requirements of the job. This flexibility is particularly useful in manufacturing custom bus bars for specialized electrical applications.

Advanced Safety Features

Safety features are critical when working with heavy machinery. Precision bus bar machines are designed with several safety mechanisms, such as automatic shut-off systems, guarded work areas, and emergency stop buttons. These features ensure that the operator is protected during the machine’s operation, reducing the risk of accidents or injuries while working with sharp or high-pressure systems.

Precision cable stripping machines are equipped with advanced mechanisms to ensure high-precision stripping of the cable insulation. The stripping blades are designed to remove the insulation cleanly without damaging the internal conductors, which is essential for maintaining the integrity of the cable and ensuring proper electrical conductivity. The machine can handle various insulation materials like PVC, rubber, Teflon, and polyethylene, ensuring versatility for different cable types.

The adjustable stripping length feature allows operators to set the exact length of the cable to be stripped, providing flexibility in stripping cable for different applications. Whether the cable is required for wiring in electrical systems, connectors, or terminals, the machine can be customized to strip specific lengths with precision. This feature is ideal for high-volume production where cables of varying lengths need to be stripped consistently.

-

Many precision cable stripping machines are designed with multi-functionality, allowing them to perform several operations in one cycle. In addition to stripping the insulation, the machine can also cut, score, slit, or sheathe the cable, eliminating the need for additional machines. The versatility of multi-function machines enhances efficiency in production environments, reducing setup time and increasing throughput.

-

Precision cable stripping machines often include an automatic feeding system that ensures consistent feeding of the cable into the machine. The cable is automatically fed through rollers or guides that align it properly before the stripping process begins. In addition, the cutting system ensures that the cable is cut to the required lengths before or after stripping. This automation reduces human error, improves speed, and ensures that the cables are fed uniformly into the machine for consistent results.

Many advanced cable stripping machines are equipped with CNC (Computer Numerical Control) technology, allowing for precise control over all machine functions. The CNC system enables operators to input specific parameters, such as the stripping length, cutting length, and stripping speed, with high accuracy. This automation reduces the risk of operator error and ensures that all cables are stripped uniformly and to the correct specifications. The system also stores program settings for repeatability in high-volume production.

Safety mechanisms are built into precision cable stripping machines to ensure operator protection. These include:

Safety guards around moving parts and blades.

Emergency stop buttons to immediately halt the machine in case of an emergency.

Safety interlocks to prevent the machine from operating unless the protective covers are securely in place.

Overload protection to prevent damage to the machine from excessive force or jams.

These features reduce the risk of injury and ensure safe operation in industrial environments.

Safety Features

High-Precision Cutting

High-Quality Linear Guides & Ball Screws

Multi-Axis Movement

Programmable and Repeatable Operations

PRECISION ROUTER MACHINE

SG Laser's precision router cutting machine is a high-accuracy tool designed for cutting, shaping, and engraving various materials such as wood, metal, plastic, and composites. These machines are commonly used in manufacturing, sign-making, woodworking, and prototyping.

Ideal for industries requiring intricate cuts and high repeatability, precision router cutting machines enhance production efficiency and accuracy.

Multi-Material Capability

Precision router machines are designed to offer high-precision cutting capabilities. These machines use a precise rotary cutting tool, often guided by CNC control, to achieve extremely accurate cuts, ensuring clean and smooth edges. Whether cutting wood, plastics, metal, or composites, the machine can handle detailed cuts with tight tolerances, which is essential in industries like woodworking, signage, and aerospace manufacturing.

One of the standout features of a precision router machine is its versatility in handling multiple materials. The machine can cut, carve, engrave, and shape a variety of materials, including wood, plastics, aluminum, composites, and soft metals. With the appropriate tooling, these machines can also process more specialized materials, such as ceramics and stone, making them ideal for use in diverse industries such as furniture making, aerospace, automotive, and packaging.

Computer Numerical Control (CNC) is a core feature of modern precision router machines, offering exceptional accuracy and automation in the cutting process. The CNC system allows operators to input exact specifications for cuts, including cutting depth, routing speed, and tooling adjustments. CNC control also enables operators to program multiple operations, which can be run without manual intervention, leading to greater efficiency and repeatability. Additionally, CNC routers can store multiple cutting programs, making them ideal for mass production runs.

-

Advanced precision router machines are equipped with multi-axis movement capabilities, typically featuring 3-axis, 4-axis, or 5-axis configurations. This means the router can move not just along the X, Y, and Z axes but also with additional rotational axes (A and B), allowing for more complex and detailed cutting operations. Multi-axis routers enable intricate cuts, bevels, and angles to be applied to the workpiece, which is necessary for high-quality 3D carvings and components with complex geometries.

-

Precision router machines use high-quality linear guides and ball screws to ensure smooth, precise, and stable movement of the machine's axes. These components contribute to the overall accuracy and repeatability of the machine, ensuring that each cut is made according to the exact specifications. The ball screw system ensures that the router’s movements are precise and that the machine can handle heavy-duty cutting tasks without losing accuracy over time.

-

The precision router machine allows operators to program multiple operations for a single workpiece. This programmable feature enables the machine to execute repetitive tasks efficiently, making it ideal for mass production. Once the parameters are set, the machine can automatically repeat the same cutting or engraving process with high consistency, ensuring that the same product is produced to the exact specifications every time.

.png)